In the recent Instructable project Introducing the Mini LED Table: Compact, Affordable, and Enhanced With Computer Vision, we presented an inexpensive, compact, and easy-to-build Mini LED Table (MLT) that is a simple and cost-effective project for a STEM activity and a tool for educational purposes. Among other applications, The device can open doors for students and educators to explore the fascinating world of material science and engineering by providing an affordable and compact solution.

In a new project on the Instructables website, I have extended the capability of the MLT by adding a device that uses polarizer filters in front of the Picamera, which will provide the capability to visualize the internal stress distribution within transparent materials. These stress patterns due to the birefringence of some materials are paramount for engineering analysis. They are significant in determining various substances’ mechanical behavior and structural integrity.

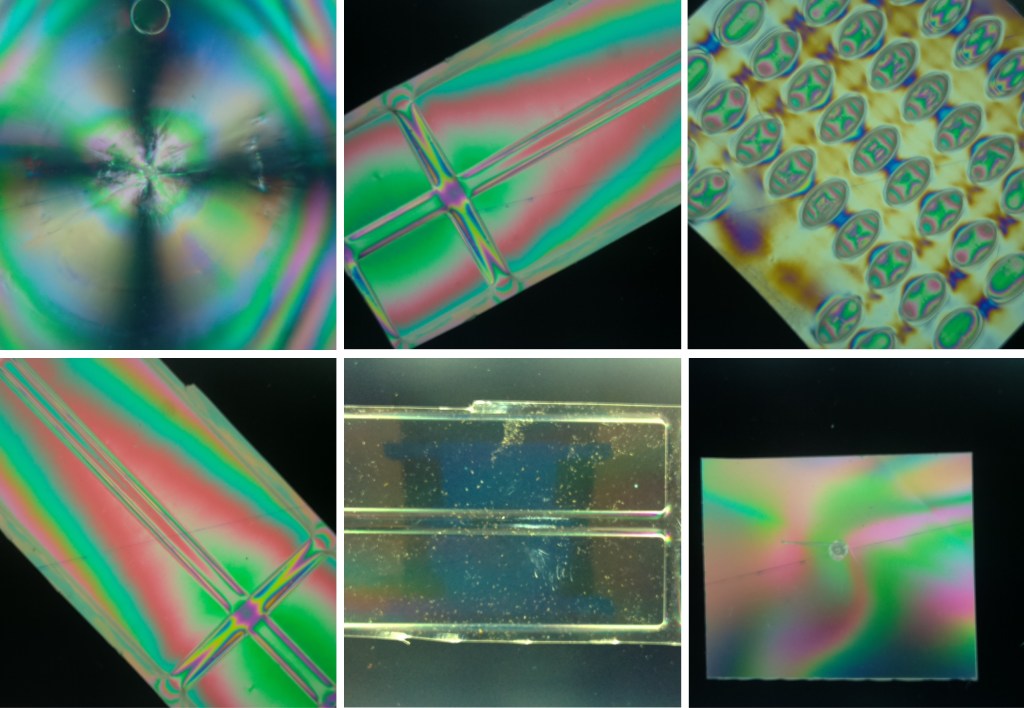

To address this possible application, we will explain how to add a polarizer to the MLT, which is already equipped with computer vision capabilities. In short, the accessory consists in adding a removable polarizer filter onto the Mini LED Table and incorporating another polarizer near the Picamera mounted on a rotatable 3D support enabling the visualization and analysis of colorful stress patterns that arise in transparent plastic and other materials exhibiting photoelastic effects.

By harnessing the capabilities of MLT, polarized light, and computer vision integration, we want to provide educators and students with a powerful tool for visualizing and understanding the intricate stress patterns present in transparent plastics and other photoelastic materials.

Before delving into the details of the project, let us provide a brief overview of photoelasticity and its significance in engineering. Photoelasticity is a powerful technique used to analyze the stress distribution in materials. It is based on the principle that the refractive index of a photoelastic material changes with applied stress. By passing polarized light through a stressed material and analyzing the resulting fringe patterns, engineers can gain valuable insights into the stress distribution and behavior of the material under various loading conditions.

Photoelasticity finds extensive applications in engineering. It aids in designing and analyzing components subjected to complex stress states, such as structural components, machine parts, and even optical devices. By visualizing stress concentrations, engineers can optimize designs, identify potential failure points, and enhance various systems’ overall reliability and performance. Additionally, photoelasticity plays a crucial role in material testing, prototype validation, and quality control processes, enabling engineers to ensure the integrity and safety of critical components.